One of the most fundamental requirements of hazard mitigation is that the mitigation itself should not create an additional hazard.

Evaluating Switches and Relays for Compatibility

Safety professionals often conclude a risk assessment then go shopping for solutions. While post-risk-assessment performance evaluations help to avoid problems in design and implementation, there is an even more fundamental evaluation that needs to take place before any products are purchased. Safety professionals must confirm that the products and components used in the mitigation are safe, reliable, and electrically compatible with the machine being guarded. Most integrators know to check voltage and current ratings but there are even bigger factors to consider when specifying relays, contactors, or other switching devices for use on power tools and industrial machinery. Those factors are the horsepower (HP) rating, which defines the maximum size of motor that the component can reliably switch, and the UL (or other NRTL) Listing Category.

Horsepower is King

Horsepower ratings are important for motor controls for two primary reasons. First – motors have incredibly high starting and locked-rotor currents. A 1.5 HP band saw may list it’s current draw at 15 amps but it will draw up to 90 amps during the first second of startup and during a locked rotor event. Second – motors are heavily inductive loads, meaning they store energy in a magnetic field during regular operation. When a switch tries to turn-off a motor and interrupt the current path the motor will generate a sustained electric arc that can cause significant damage to electrical contacts. For these reasons, using a motor with an inadequately rated switch or relay is likely to result in welded contacts (making it impossible to switch off the machine), premature switch failure, and/or fire.

An Example to Illustrate the Point

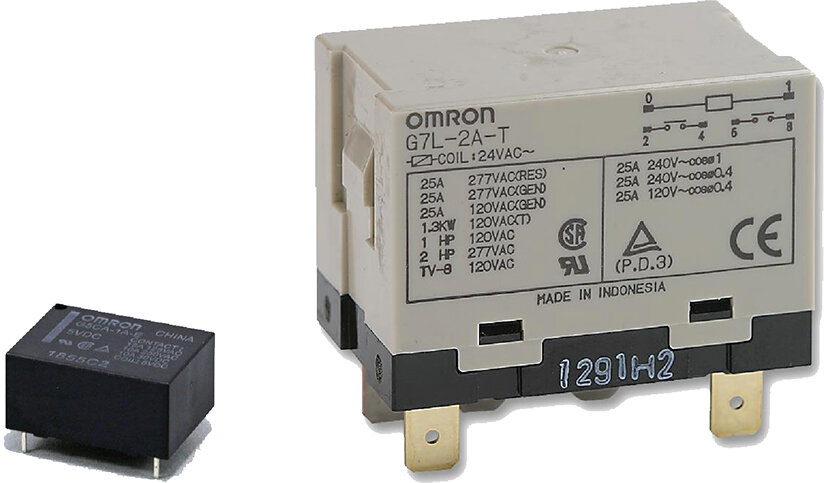

A quick google search for “accidental restart prevention” or “tool switch” will yield loads of advertisements and products promising to solve your problem but don’t trust the marketing or the pictures of these devices being used on saws and equipment. To illustrate this point, the scale image below shows two relays which act as the primary switching component in two accidental restart prevention devices currently on the market. Both products are rated for 15 amps and pictured in marketing materials next to industrial machinery.

The key difference is that the relay on the left is contained within a device that does not list a HP rating while the relay on the right is contained within a product that is rated for a 1.5HP motor. Their physical size difference is just one of many factors that make the larger relay capable of safely connecting and disconnecting a motor for thousands of cycles. Luckily – you don’t have to wade through datasheets to determine what products are HP rated and which aren’t. You just need to look for the listed mark of a Nationally Recognized Test Lab and the HP rating marked directly on the device.

UL (NRTL) Listing Isn’t Enough

You might think that the familiar UL listing mark means a device is safe to use on your machinery but that is not necessarily the case. Nationally Recognized Test Labs list products based on a category. If we return to the two products we compared above, and look at their documentation and markings, they both have an NRTL mark. However, they are listed for different categories. The under-rated one (with the tiny relay) is listed as an “Appliance Control” while the horsepower-rated device (with the big relay) is listed as “Industrial Control Equipment”. A quick glance at UL’s description of each category makes the difference clear.

UL Category: Appliance Controls

“This category covers controllers … [with] one or more output switching components to directly control all or a portion of household-type appliances, such as portable luminaires, audio/video equipment, etc.”

“They are not intended for controlling motor-operated appliances”

UL Category: Industrial Control Equipment

“These requirements cover industrial control devices, and devices accessory thereto, for starting, stopping, regulating, controlling, or protecting electric motors. ”

It should come as no surprise then that installing products listed as an “Appliance Controls” on a motor can lead to complete device failure and fire.

In Summary

Before purchasing any device that will be installed upstream of a power tool, piece of machinery, or any other motor, make sure to check the following:

- Verify that the device is listed by a Nationally Recognized Test Lab and intended for use as a motor control. It should be marked as such on the product itself.

- Verify that the device is rated in horsepower and that the rating matches or exceeds the horsepower of the motor you’re planning to use it with.

The MAKESafe Power Tool Brake

You’ve probably already guessed it but the properly rated device described above (with the large horsepower rated relay) is our power tool brake. Our products are all UL508 Listed Industrial Controls. This means our devices have undergone intense endurance and short-circuit tests to verify their ability to handle the intense demands of industry.